Sino Polymer, in collaboration with East China University of Science and Technology (ECUST) and Shanghai Huayi Group, focuses on the scientific and technological innovation of new polymer materials and the transformation of research achievements. The company hosts several key research centers, including the Shanghai New Anti-Corrosion Materials Engineering Technology Research Center and the Shanghai Enterprise Technology Center, and operates an academician expert workstation. Sino Polymer has filed 118 invention patents, with 75 already authorized. Additionally, the company has participated in the development of nearly 50 national and industry standards and has undertaken eight national and Shanghai-level scientific research projects. Through close cooperation with ECUST, the Institute of Chemistry at the Chinese Academy of Sciences, Commercial Aircraft Corporation of China (COMAC), Shanghai Petrochemical, and Donghua University, Sino Polymer fosters industry-academia-research collaboration. This partnership drives continuous innovation, forming new high-quality productivity and promoting advancements in technology, industrial upgrading, and the enhancement of the product value chain. This collaborative approach ensures that Sino Polymer remains at the forefront of its field, contributing significantly to both national and international standards and technological progress.

The Shanghai Municipal Party Committee’s Office of Military-Civil Fusion has strategically endorsed the co-establishment of the Sino Polymer Industry & Technology Research Institute by East China University of Science and Technology (ECUST) and Shanghai Huayi Group. This initiative advances the development of military-civil dual-use polymer materials, while facilitating the creation of pilot production lines and testing facilities at Sino Polymer’s designated production base (No. 130 Muhua Road, Shanghai Chemical Industry Park). In September 2023, Sino Polymer was designated as one of Shanghai’s inaugural pilot enterprises for the New Materials Innovation Base program, demonstrating its pioneering status in industrial-academic collaboration and technological commercialization.

This strategic partnership strengthens core infrastructure for material innovation, accelerates technology transfer mechanisms, and fosters an integrated ecosystem spanning R&D, pilot testing, and industrial-scale production – positioning Sino Polymer as a key driver of China’s advanced materials sector. Sino Polymer has forged its technological leadership through three decades of strategic integration across industry, academia, and research ecosystems. The company’s R&D engine is powered by an elite team of over 100 distinguished professionals, including recipients of China’s most prestigious honors such as the National Labor Model, State Council Special Government Allowance, and National Top Ten Outstanding Entrepreneurs in Corrosion Protection. Shanghai municipal recognition further highlights the team’s excellence through accolades including Shanghai Labor Model, Leading Talent designation, and Top Ten Science & Technology Entrepreneurship honors. This multidisciplinary collective combines academic authority from professors and postdoctoral researchers, advanced technical mastery through PhD and Master’s degree holders, and industry-proven expertise from senior engineers specializing in applied technology commercialization. Their synergistic collaboration drives continuous innovation in polymer material development, supported by Shanghai’s recognition of the team’s outstanding contributions to high-tech industrialization. This convergence of award-winning talent and technical excellence positions Sino Polymer at the forefront of material science innovation.

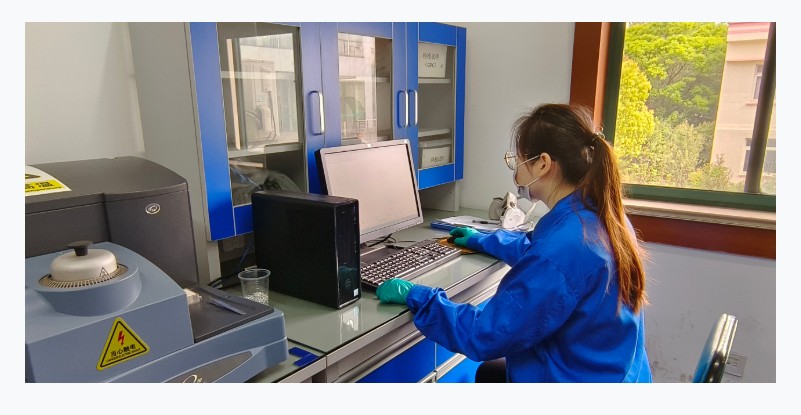

Sino Polymer’s laboratory features ISO-certified analytical instrumentation that is capable of performing experiments including thermal analysis, spectroscopic systems, microscopy and rheology, mechanical testing, combustion analysis, environmental simulation and polymer-specific testing. Sino Polymer’s pilot-scale facilities support advanced manufacturing techniques including Pultrusion, RTM/Injection Molding, SMC/BMC Compression Molding, Prepreg Layup, and UV-Curing Processes, along with other specialized forming technologies.

For detailed information, please refer to the Instrumentation and Equipment